ROBOTIC CAMERA SYSTEM

motion control Robotic Camera Systems

ROBOTIC CAMERA SYSTEM

SIMPLE + FLEXIBLE + AFFORDABLE

ROBOTIC CAMERA SYSTEM

+ SIMPLE + FLEXIBLE + AFFORDABLE

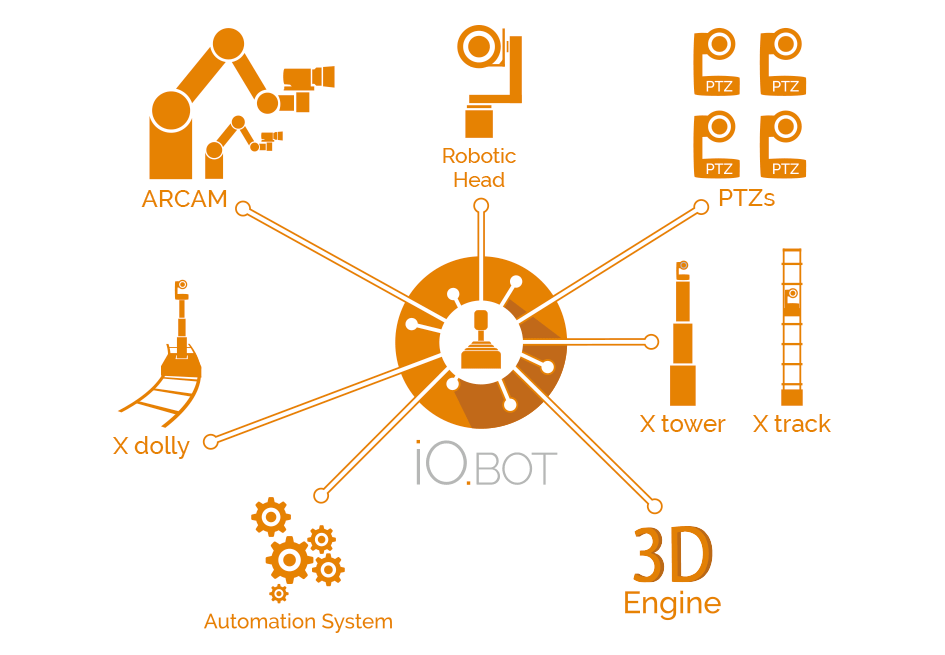

One system, plenty of possibilities

ROBOTS

IO.BOT software allows a single operator to control up to 16 motion control robotic camera systems including one robotic arm (ARCAM) and multiple PTZs.

HMI

IO.BOT software and remote controller allow full control of your motion control robotic systems and centralize your production easily and fast!

PLUGINS

Connect any 3D Engines and add Augmented Reality to your shootings.

Connect your robotic camera systems to your Automation System and control everything from your control room.

Advantages

Case studies showing a quick return on investment

Proven reliability from real use cases from customers

Robots backed by an international customer service agreement

Simple to install, easy to use and intuitive to operate.

Specifications

6 axis motion control arm

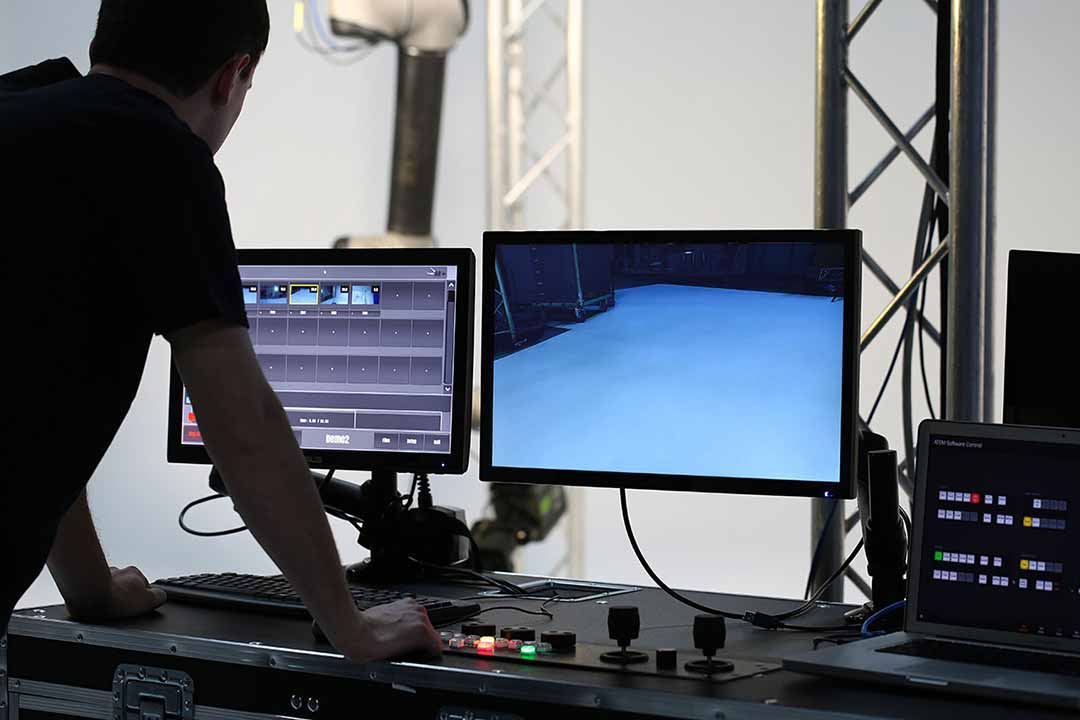

Everything is controlled from the control room

Fully compatible with studio and control room devices

Benefits

Artistic

+ Movements – Perfect for beauty shots

+ Precision – Smooth for perfect shots

+ Design – Can be used on set design

Ergonomics

+ Silent movements for live broadcast use

+ Confined space – Install where jib can’t

+ Can be fixed and rig everywhere

Safety

+ Proximity detection security and hard stop

+ COVID and safety compliance

+ Built to work with people

Connection

+ 3D Engine AR, XR, VR connections

+ 100% IP & 5G remote production

+ All Broadcast robotics supported

Take advantage of the full speed range and accelerations while lifting the maximum payload at it’s maximum reach with the new ARCAM 20

motion control axis

kg weight (base configuration)

m reach (ARCAM 20)

kg payload (ARCAM 20)

m diameter sphere (ARCAM 20)

ARCAM 10 Technical Specifications

Reach : 1200 mm / 47,2 in

Payload : 12,5 kg / 27,55 lbs

Weight : 33,5 kg / 73,9 lbs

Joint ranges : ± 140° for base, ± 180° for pan, ± 80° for tilt, ± 80° for roll

Speed : Camera : Approx. 1 m/s / 39,4 in/s

Repeatability : ± 0,1 mm / ± 0,0039 in (4 mils)

Grip / footprint : Mitchell and Vinten mounts

Degrees of freedom : 6 rotating joints

Noise : Noiseless

IP classification : IP54

Power consumption : 615W

Power supply : 100-240 VAC, 50-60 Hz

Collaboration operation : Collaborative operation according to ISO 10218-1:2011

Dolly Technical Specifications

3 Meter Version :

Weight : 130 kg

Payload : more 1.000 kg

Track Size : 300 cm x 60 cm x 50 cm

Repeatability : ± 0,1 mm

IP classification : IP54

Power supply : 100-240 VAC, 50-60 Hz

4 Meter Version :

Weight : 140 kg

Payload : more 1.000 kg

Track Size : 420 cm x 65 cm x 50 cm

Repeatability : ± 0,1 mm

IP classification : IP54

Power supply : 100-240 VAC, 50-60 Hz

Power consumption : 530 W

Fixed Stand Version :

Weight : 60 kg

Payload : more 1.000 kg

Track Size : 120 cm x 110 cm x 125 cm

Moving with wheels

ARCAM 20 Technical Specifications

Reach : 1750 mm / 68,9 in

Payload : 20 kg / 44,1 lbs

Weight : 64 kg / 141,1 lbs

Joint ranges : ± 140° for base, ± 180° for pan, ± 80° for tilt, ± 80° for roll

Speed : Camera : Approx. 1 m/s / 39,4 in/s

Repeatability : ± 0,1 mm / ± 0,0039 in (4 mils)

Grip / footprint : Mitchell and Vinten mounts

Degrees of freedom : 6 rotating joints

Noise : Noiseless

IP classification : IP65

Power consumption : 800W

Power supply : 100-240 VAC, 50-60 Hz

Collaboration operation : Collaborative operation according to ISO 10218-1:2011

PTZ CONTROL

The IO.BOT software is universally renowned for its ergonomic interface, which has been designed by our talented engineers with a focus on end-user experience.

With our software, you can control up to 16 PTZs from leading brands such as Sony, Panasonic, Canon, and PTZ Optics simultaneously, allowing you to manage everything from a single location.

The IO.BOT software offers clients a triple win, saving them space, time, and most importantly, money!

Key Benefits

Centralized interface – Control up to 16 PTZs with only one interface

Map control

Maintenance and security monitoring

Compatible with VSM

Video grid control – Compatible with any brand

Tally management

X TOWER

The X tower is a remotely controlled skate movement system. Due to its discretion, it is perfect for studios, vertical, on the ground or on the ceiling, and it is able to hide quickly. Its tracks precision capability allows to broadcast on the move, from PTZs, remote head or ARCAM.

Key Benefits

Stroke from 55cm to 80cm

Noiseless and speed up to 4cm/s

Can be mounted upright or upside down

Can be used for PTZ, remote head and ARCAM

Full motion control with IP

Full FreeD tracking compatible

Cable management carrier included

Key Benefits

Centralized interface – Control up to 16 PTZs with only one interface

Map control

Maintenance and security monitoring

Compatible with VSM

Video grid control – Compatible with any brands

Tally management

Key Benefits

Control your ARCAM and all your PTZs

Define as many trajectories as you want

Can be connected to any 3D engines

Control with your automation system

User-friendly

IO.BOT SOFTWARE

IO.BOT is the ARCAM System control software platform.

Developed by our world leading engineers in partnership with camera operators, its interface is ergonomic and optimized for broadcast use.

It ensures smooth movements with huge accuracy and repeatability offering a unique user experience.

Connect your 3D engine and IO.BOT will collate, manage and report data from all of your connected robots.

Software Minimum Specifications

Windows 10

Core i7 3.8 GHz min.

Video card (suitable for 3D rendering and directX) min. 2 GB dedicated

16 GB RAM min.

30 GB disk space

Software designed to work with touch screen.

Optional : SDI acquisition card (USB 3.0 / PCI-e)

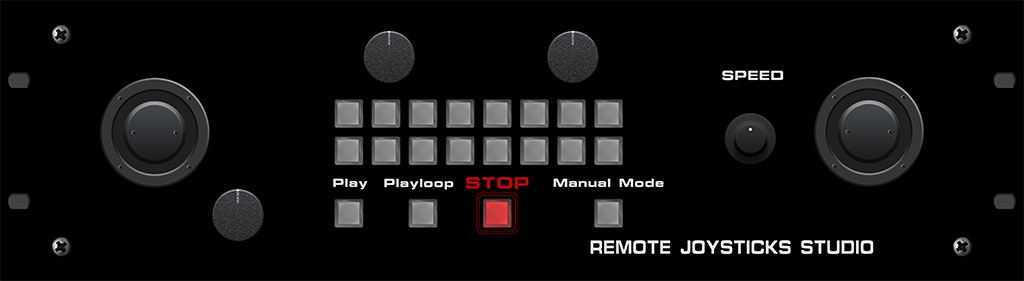

JOYSTICKS REMOTE

Key Benefits

Manage as many trajectories as you want

Make any complex movements you desire

Assign whatever you want to the joysticks and buttons

Our remote has :

+ 2 Joysticks used for camera translations, rotations and zoom

+ 3 rotary encoders to manage focus, iris, and zoom

+ 16 switches to choose which robot to start

+ “Stop” button

+ “Play” button

+ “Manual Mode” button

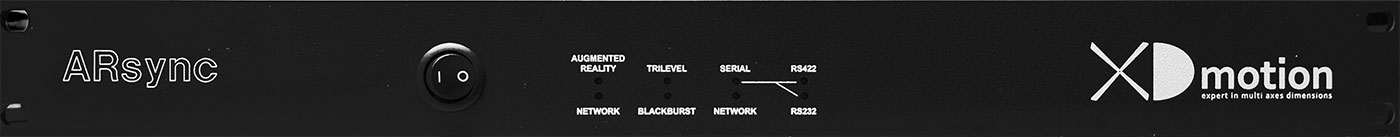

3D engines and Augmented Reality

You can plug a hardware developed by XD motion to the robotic arm and to your 3D engine. Then, thanks to free-d protocol, you can get all the robot information in real time.

This solution is compatible with any 3D engines.

Centralize all your control room’s commands

Thanks to our plugin, connect your robotic arm and/or your PTZs to your automation system. This plugin is compatible with any automation systems thanks to our API (GPIO connection on demand).

Key Benefits

Universal – Compatible with any automation systems thanks to our API

IP control